Perimed

- Company Logo:

- Name: Anna Norlander

- Position: Senior Project Manager

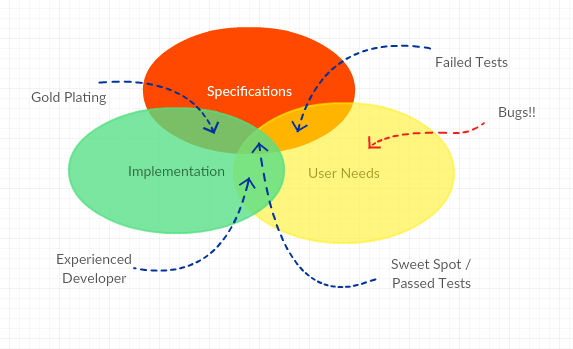

Aligned Element have made life easy working with requirement/verification including traceability. We could easily make a structure suitable for us, for all our different products and their specifications.